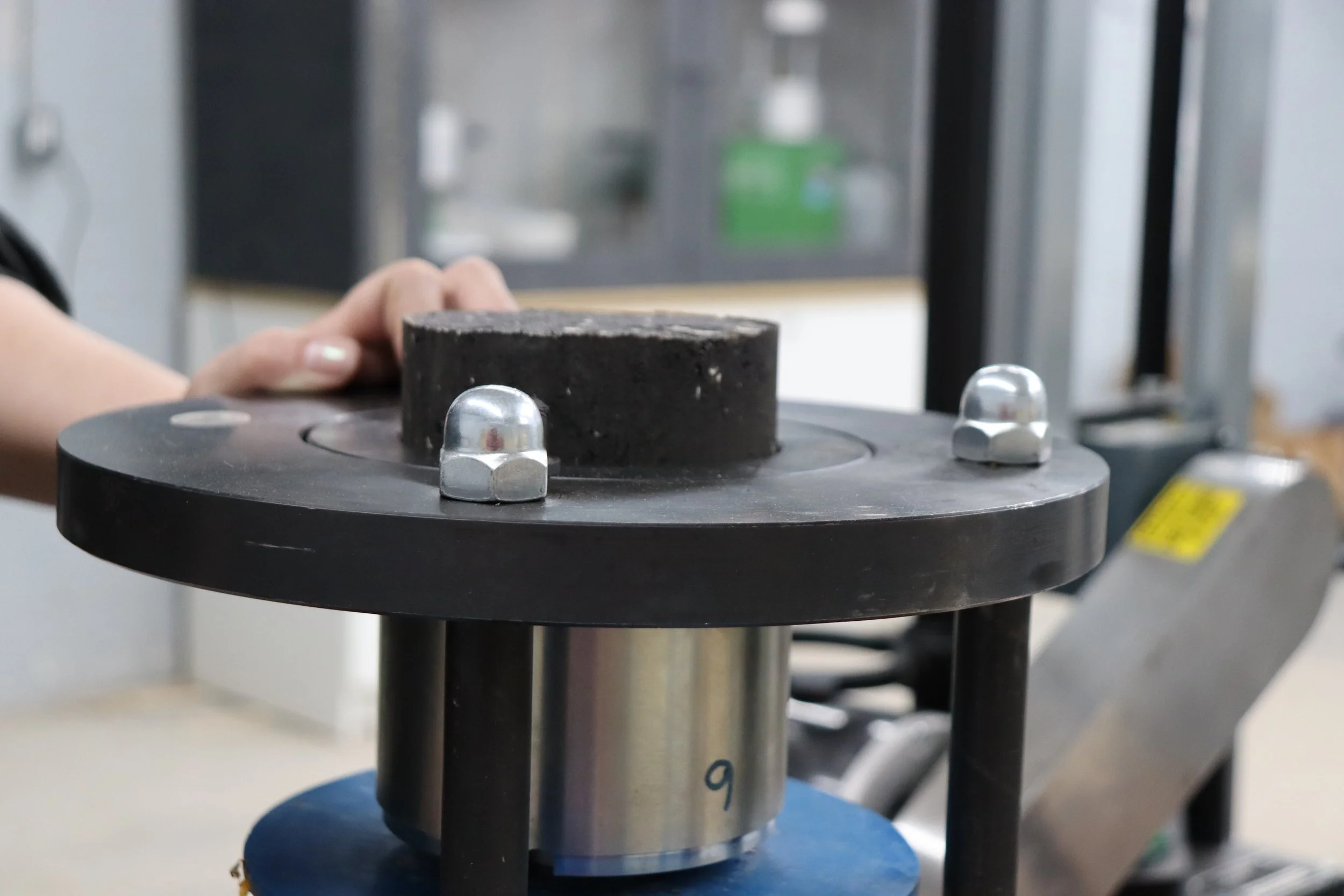

ASPHALT MARSHALL AND SUPERPAVE ANALYSIS

OVERVIEW

Our in-house asphalt laboratory provides comprehensive Marshall and Superpave testing to assess asphalt mix performance for road construction and rehabilitation projects. These tests evaluate critical properties such as stability, flow, air voids, and volumetrics to predict long-term pavement behavior under traffic and environmental stress.

We test asphalt mixes to ensure compliance with Ontario Provincial Standard Specifications (OPSS), municipal requirements, and traffic category designations. This testing supports quality control during mix design and production, verification of pavement designs, and troubleshooting of performance issues such as rutting, cracking, or premature failure.

Asphalt Mix Compliance Superpave Method (Type B)

KEY BENEFITS:

STANDARD COMPLIANCE

Confirms that asphalt mixes meet OPSS specifications, municipal requirements, and are suitable for their intended traffic category and environmental conditions.

PERFORMANCE EVALUATION

Assesses stability, flow, air voids, and volumetrics to predict long-term pavement durability.

DESIGN VERIFICATION

Validates that asphalt mixes are compatible with design assumptions and expected loading conditions.

PROBLEM-SOLVING

Aids in diagnosing and resolving pavement performance concerns, including rutting, low compaction, and premature wear.

WHEN YOU NEED IT:

DURING NEW MIX DESIGN OR PRODUCTION

To verify compliance with project specifications and ensure durability before placement.

AS PART OF PAVEMENT DESIGN REVIEWS

To confirm that selected mixes are appropriate for anticipated loading and climate conditions.

FOR MUNICIPAL OR MTO PROJECTS

Where compliance with OPSS and local specifications is required.

WHEN INVESTIGATING PAVEMENT DISTRESS

To determine whether failures are mix-related and guide appropriate corrective actions.

Asphalt Mix Compliance Marshall Method (Type B)

GEOTECHNICAL LABORATORY ENGINEERING SERVICES

SOIL TESTING SERVICES

Laboratory soil testing is essential for accurately characterizing subsurface conditions and ensuring the ground can support your building or infrastructure. Understanding soil properties helps you make informed design decisions and adapt your plans if needed. Reliable geotechnical testing lays the foundation for safe, durable, and code-compliant construction.

CONCRETE TESTING SERVICES

PRI Engineering’s Canadian Council of Independent Laboratories (CCIL)–certified concrete testing laboratory performs compression testing and on-site evaluations to help you meet your quality goals. The results from your concrete testing report give you the confidence that your concrete meets the strength, consistency, and performance standards required for project success.

AGGREGATE TESTING SERVICES

Our aggregate testing services ensure your materials meet applicable industry standards and project specifications — reducing the risk of failure, improving consistency, and supporting the success of your construction from the ground up.

T-TIME ANALYSIS

Our T-Time Analysis plays a vital role in septic system design by evaluating the soil's filtration rate and determining how efficiently water moves through the soil layers. Through a combination of laboratory testing and in-situ field evaluations, we provide a detailed understanding of site-specific soil conditions.

THERMAL RESISTIVITY TESTING

Our Thermal Resistivity Testing service offers precise analysis of soil and material properties to evaluate thermal conductivity, critical for ensuring the efficiency and safety of underground power cables and other buried utilities.